Trust Us With Your Next Project!

Established in 2006, we are locally-owned and operated by a veteran

Concrete is a very rigid material however it has a natural weakness when it comes to tension. It is limited with respect to the length of a beam, floor, or bridge can be made out of it.

One way to be able to build these structures with longer spans than would be possible with ordinary concrete is through a technique called pre-stressing. A post-tension slab is a slab of concrete pre-stressed using a specific method to increase the strength of the concrete.

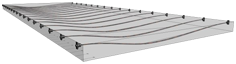

Several methods exist for pre-stressing concrete, with post-tensioning being a very common one. Before a post-tension slab is poured, high-strength steel strands or cables, called tendons, are laid in a tight grid. These support and give strength to the slab once cured. The tendons are sheathed in plastic to avoid directly touching the concrete. After the grid is made, the concrete is poured, with extra care taken to ensure it is level.

Many modern homes are built on a post-tension slab, which serves as an excellent foundation. This method of pre-stressing concrete is especially useful where the soil expands and contracts relative to weather conditions.

Using a post-tension slab rather than ordinary concrete often makes good economic sense. There is a smaller depth of concrete used to obtain the same end result, construction costs are reduced. This particular advantage has even larger implications for commercial applications.